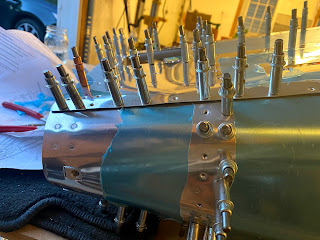

I’m also working on the spars at this point. Chapter 25 is moving quickly and I have even prepped a few of the parts for Chapter 26.

Monday, December 28, 2020

Holiday progress

I’m also working on the spars at this point. Chapter 25 is moving quickly and I have even prepped a few of the parts for Chapter 26.

Sunday, December 20, 2020

Part Prep (Deburr, Dimple, rinse, repeat (Chapter 25, 26)

I mentioned in the last post that the Inventory was complete. That is true and it turns out that Vans made a couple of mistakes. They sent some bearings which were female instead of male so they swapped those. I then discovered that they sent me 54 nutplates that were 3/8" sized (K1000-6 instead of K1000-06 - way way smaller). I am not sure where you would even use a 3/8" nutplate in a Vans aircraft but they had enough to send me 54 of them. I returned those as well and am waiting for replacements.

Thursday, November 19, 2020

Inventory complete

Saturday, November 14, 2020

Inventory under way!

| Much sturdier table |

| A little too soon to be thinking about the panel |

Friday, November 13, 2020

Fuselage kit has Arrived!

It's here! I am still building my second new table so I will be opening it up later tonight and taking a look. Old Dominion came through with no damage at all on the outside crate.

Thursday, November 5, 2020

Fuselage kit has SHIPPED!

Exciting news from the mothership. I just received a notice from Old Dominion that the Fuselage kit along with a couple of replacement skins for the tailcone has shipped!

Time to clear out the shop this weekend!

For those that are curious, time from ordering to shipping was 15 weeks. Original quote was 10 weeks, however COVID and the wildfires added an extra five.

Stay tuned!

Saturday, October 10, 2020

Left side skin re-do

I had already mis-dimpled one of the holes in the left side aft skin and was able to upsize the rivet. Unfortunately due to some unique circumstances a decent sized dent was made in the assembled tailcone and I have chosen to redo the left side which unfortunately will require disassembly.

Luckily because of the fuselage kit delay, I have a crate coming from Vans which allows me to get skins and stiffeners shipped basically for free as it just gets thrown into the crate (or more accurately REALLY duct taped and papered in).

More to come

Monday, September 28, 2020

Fuse Kit Shipping Delay

So today was supposed to be the date that crating began for my fuselage kit. Unfortunately I was informed late last week that shipping is now delayed by 4-6 weeks, so my total wait could be like 3-4 months since I ordered. This is really unfortunate and I do understand the issues with the fires up there however it just seems like the message was a little off from when I ordered. Covid was already in full swing and the crating date was supposed to be today. When I asked about why the delays were 4-6 weeks more I was told it was because of the fire issues as well as Covid (I was expecting maybe a 1-2 week delay given they just started shutting down a week or two ago for the fires)

On a more positive note, this allows me to start working on fiberglass perhaps. I have to look more into what is involved in it as I was originally going to wait until the end of the project to work on it other than the canopy.

Saturday, September 12, 2020

Waiting for the Fuselage Kit

Progress continues, although right now is a bit of a lull in the project. I only have around 45 minutes of riveting to go before the tailcone is complete. Finding helpers has been somewhat of a challenge but this will be resolved soon. The only remaining rivets are the very top ones in the middle of the top skin. I plan on climbing in and having someone rivet from the outside.

My current crating week is September 28, and I was hoping that somehow it would ship sooner but it is so unfortunate what is happening with all the fires out west that this looks unlikely.

I have chosen for now based on advice in the forum to delay all fiberglass work until the end of the project, although if the Fuselage kit gets delayed a lot more I may reconsider that and work on the tips for the rudder and elevators. Chapter 11+12 I find quite confusing as it seems like this is where you would mount the tail surfaces on a permanent basis and this is not at all what I want to do right now.

Stay tuned, it's time to clean the garage and take care of all the other projects while I wait!

Tuesday, July 28, 2020

Tailcone work continues - Ordered Fuselage Kit

Wednesday, June 24, 2020

Working on the very aft of the aft fuselage

Saturday, May 16, 2020

I am back to building yet again

I am working through chapter 10, and am setting up some timelapse video which I intend on posting here on the blog as I complete sections.